VaproShield WRB/Air Barriers Ideal for Pre-Panel Manufacturing and Fabrication

EXCEPTIONAL DURABILITY

Tested to the extreme. PanelShield SA was used on a modular NOAA weather station headed to Antarctica with installation expected in late 2022. Air tight and breathable PanelShield SA will help to save energy, reduce air infiltration, and protect the building envelope from extreme winds and temperature fluctuations.

|

|

BUILT TO PROTECT

Weather and supply chain delays didn’t slow down this project. With windows over three months out, PanelShield SA was installed over all the walls and rough openings protecting the structure and simultaneously aiding in drying-in the residence, allowing work to continue.

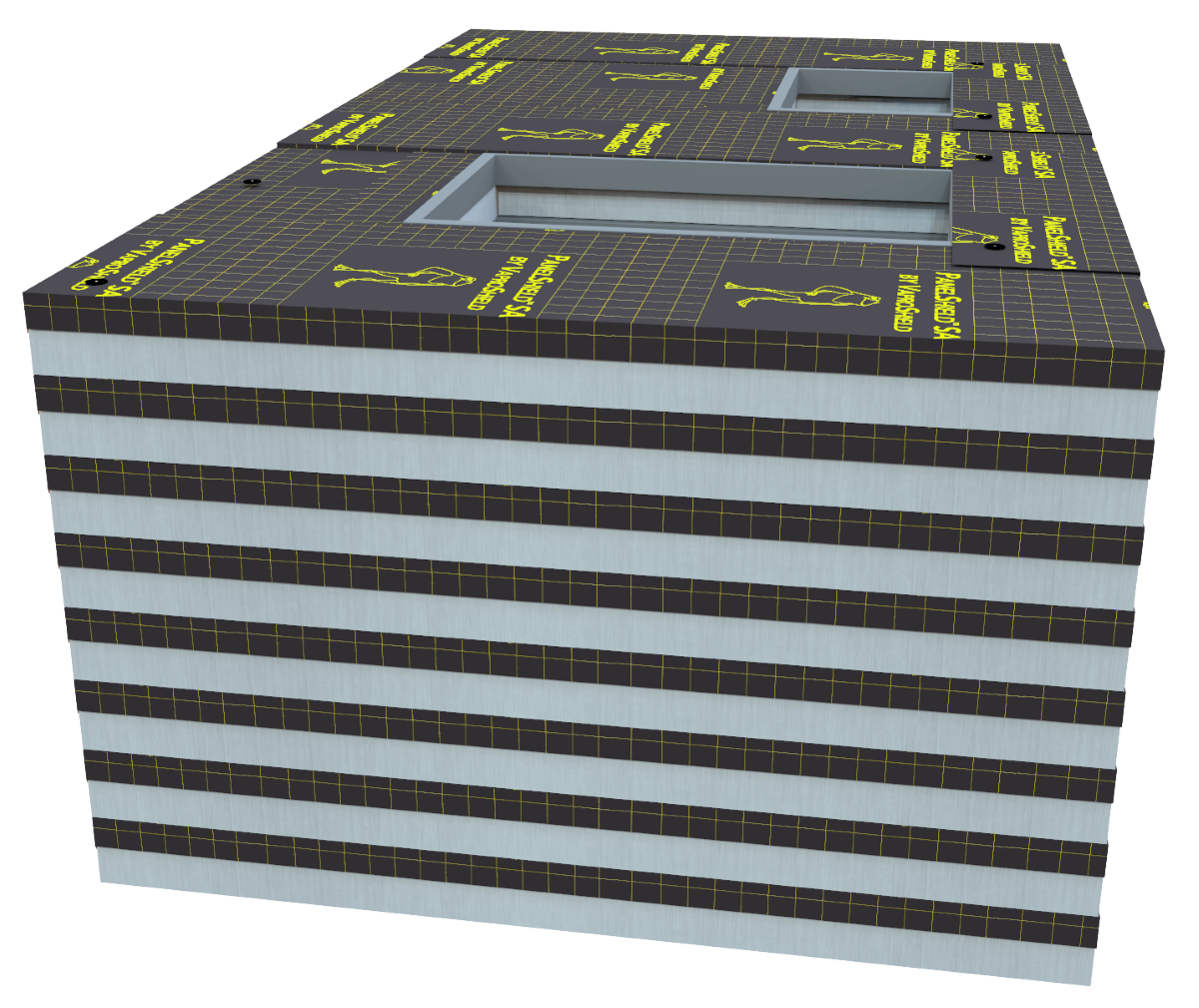

OPTIMIZED FOR PANELIZED CONSTRUCTION

|

|

|

EFFICIENT FACTORY INSTALLATION

Fast in-plant installation, zero VOCs, no primer, easily cut to size, means minimal crew training and keeps factory lines moving. PanelShield SA requires no substrate joint reinforcement or screw hole taping, and bridges gaps up to 7/8”

|

|

FIELD INSTALLATION

VaproShield has prepared “Best Practice Sequence for Field Installation” for work crews. The step-by-step pictorial guide outlines floor-to-floor installation ensuring membrane courses are properly shingled and vertical seams are accurately sealed.

|

|

|

FACTORY SAFE, WORKER SAFE

PanelShield SA ensures crew safety and a health building, no VOC exposure, no primers, or protective gear are required for installation.

|

|

INCREASE YOUR PROFITABILITY TODAY

PanelShield SA meets/exceeds all relevant codes for air barriers and weather resistive barriers. It’s proven field performance will enhance your bottom line.