QUICK OVERVIEW

VaproAirSeal™ an air and watertight single component sealant fills gypsum seams and fasteners in preparation for fluid-applied air barrier

VaproAirSeal™ an air and watertight single component sealant fills gypsum seams and fasteners in preparation for fluid-applied air barrier

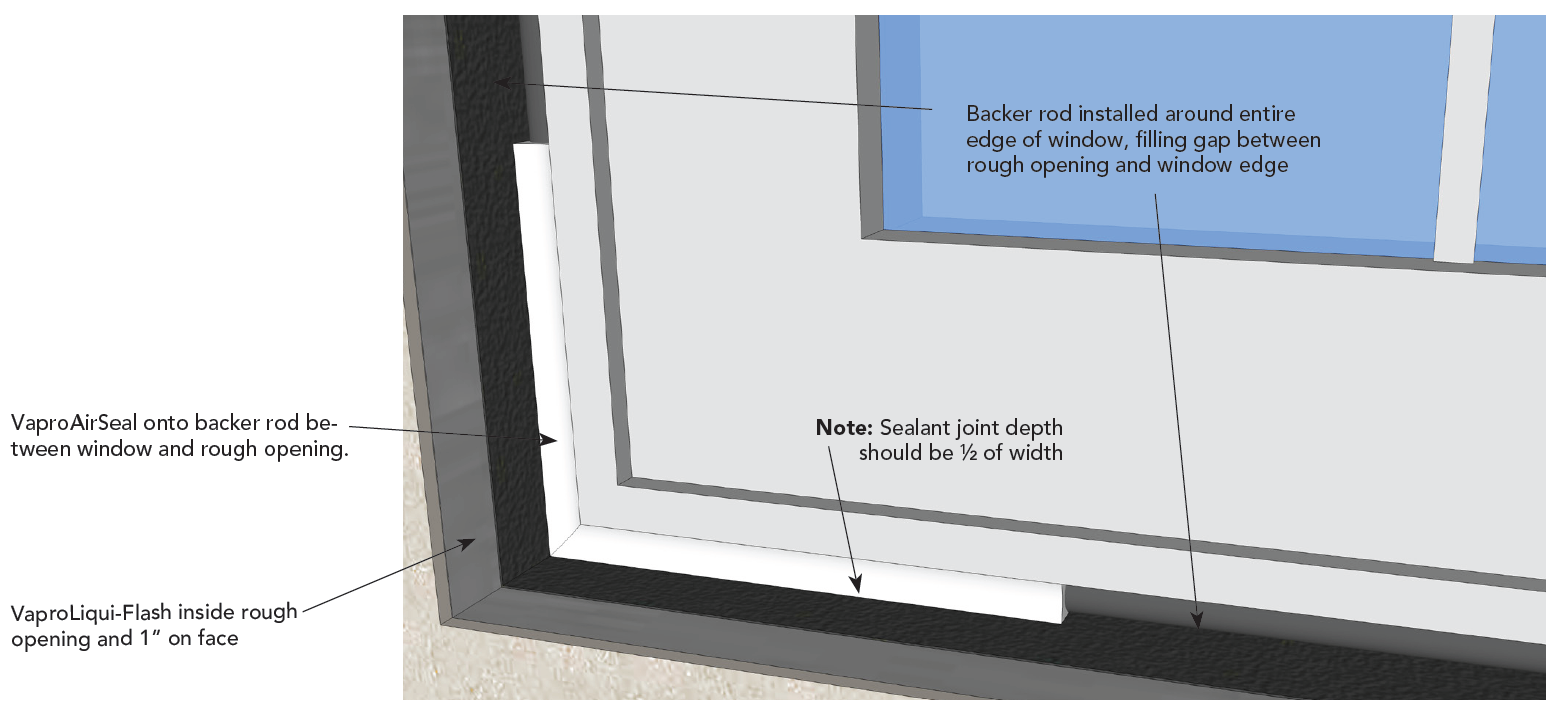

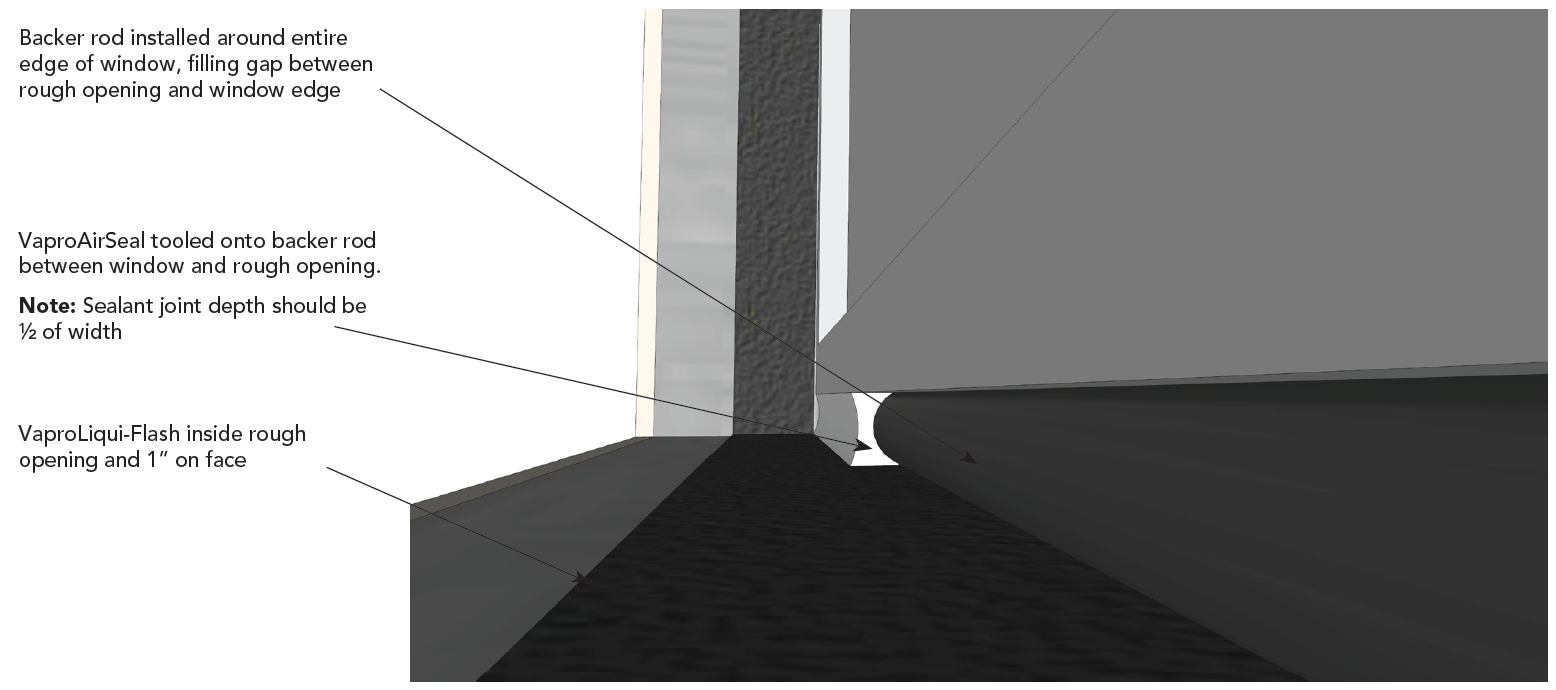

- Improves air and water tightness of fenestration systems; sealing the interior window frame to the window rough opening flashing.

- Air and watertight - bonds to VaproShield materials without primers (or priming).

- Minimum application temperature: 35°F (1.7°C).

- Permanently Flexible - allowing for +/- 50% joint movement.

- Paintable – in two (2) hours

- Emits very low VOCs – contains no solvents.

- Compatibility - Compatible with all VaproShield membranes and accessories.

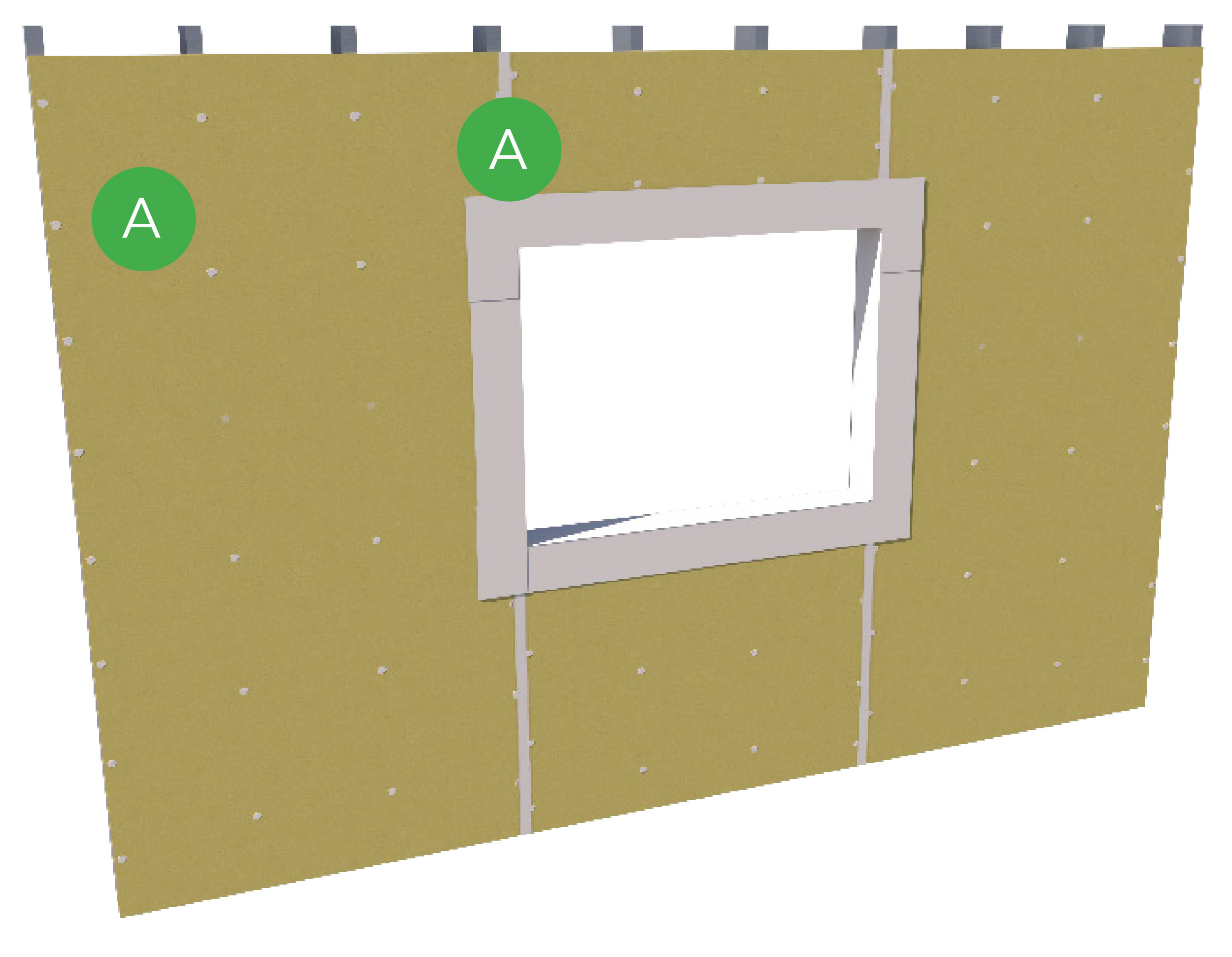

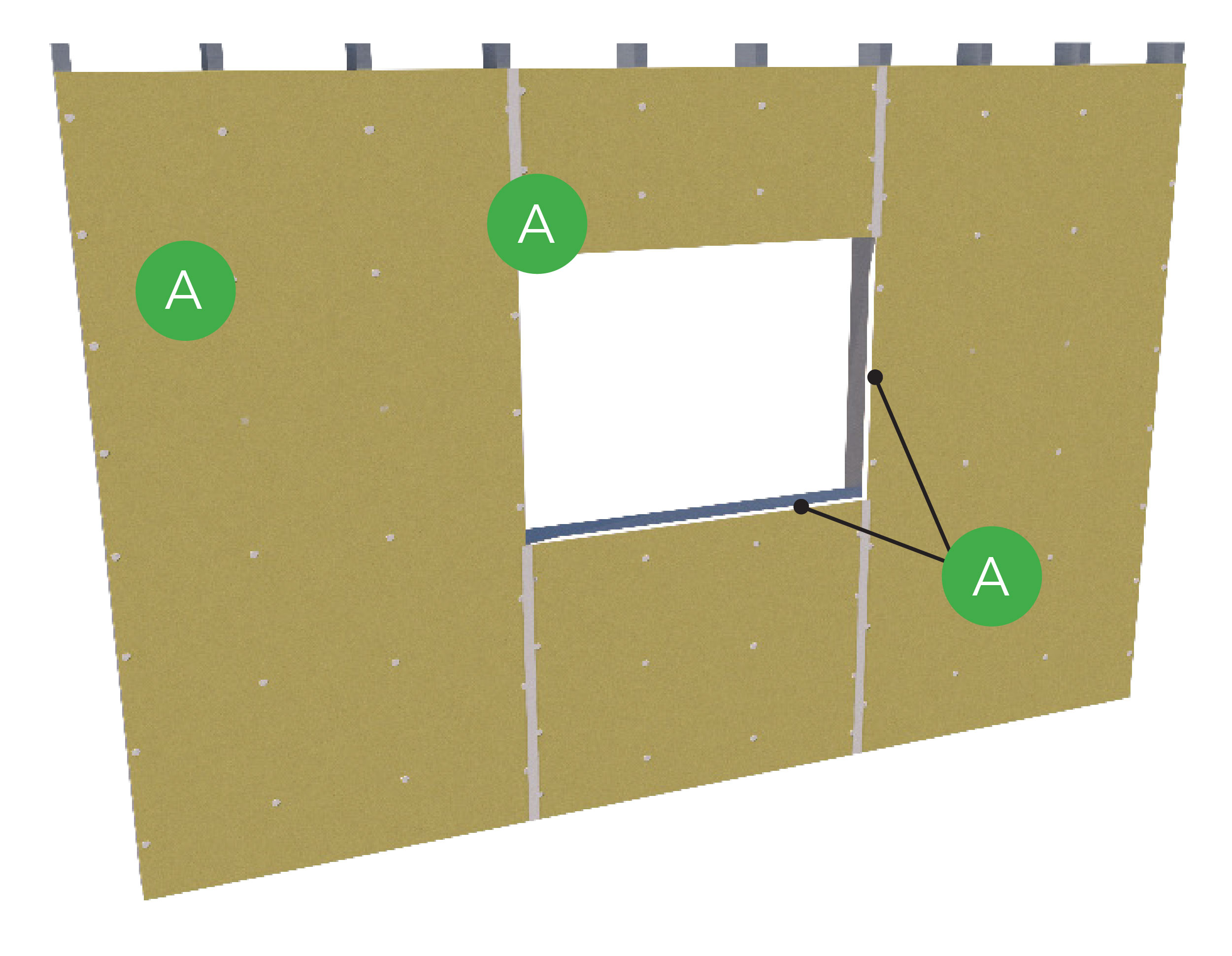

Typical VaproAirSeal Applications with VaproLiqui-Shield

|

|

| Tool VaproAirSeal on seams less than 1/4" and fasteners in preparation for VaproLiqui-Shield fluid-applied air barrier. | Tool VaproAirSeal on seams less than 1/4", fasteners and along any raw edges of gypsum sheathing in the rough opening. |

Typical VaproAirSeal Applications

|

|

Resources

Testing Data

| PHYSICAL PROPERTIES | |

| Sizes/Packaging | 20 fl. oz, 591 ml. Sausage 20 sausages per box |

| Minimum Application Temperature | 35°F (1.7°C) |

| Service Temperature | -40°F (-40°C) - 200°F (93°C) |

| Skin Time | Less than 20 min. @ 77°F (25°C)/50% RH |

| Tack Free Time | < 60 minutes @ 25 °C (77 °F)/ 50% RH |

| Cure Rate | ¼” (6.35 mm) 48 hours |

| VOC | < 23 g/L |

| Elongation @ Break | 200-250% |

| UV Rating | No discoloration or change in appearance after 2500 hours of UV |

| Lap Shear | 0.62 MPa (90 psi) |

| Tensile Strength | 1.03-1.38 MPa (150-200 psi) |

| TESTING DATA | ||

| PROPERTY | STANDARD | RESULT |

| Durometer Hardness, Shore A | ASTM C661 Standard Test Method for Evaluating Degree of Cracking of Exterior Paints | 35 +/- 5 |

| Tensile Strength | ASTM D412 Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension | 1.03-1.38 MPa (150-200 psi) |

| Elongation at Break | ASTM D412 Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension | 200-250% |

| Lap Shear | ASTM C961 Standard Test Method for Lap Shear Strength of Sealants | 0.62 MPa (90 psi) |

| Low / High Temp Flexibility | minus 90°F (-68°C) / 425°F (218°C) | |