Quick Overview

BlockFlashing is a self-adhered, non-asphaltic, air, water, and vapor barrier flashing.Self-Adhered, Non-Asphaltic, Air, Water, and Vapor Barrier Flashing

BlockFlashing is a self-adhered, non-asphaltic, air, water, and vapor barrier flashing.Self-Adhered, Non-Asphaltic, Air, Water, and Vapor Barrier Flashing

- Non-Asphaltic product

- Impermeable to air, moisture vapor, and water

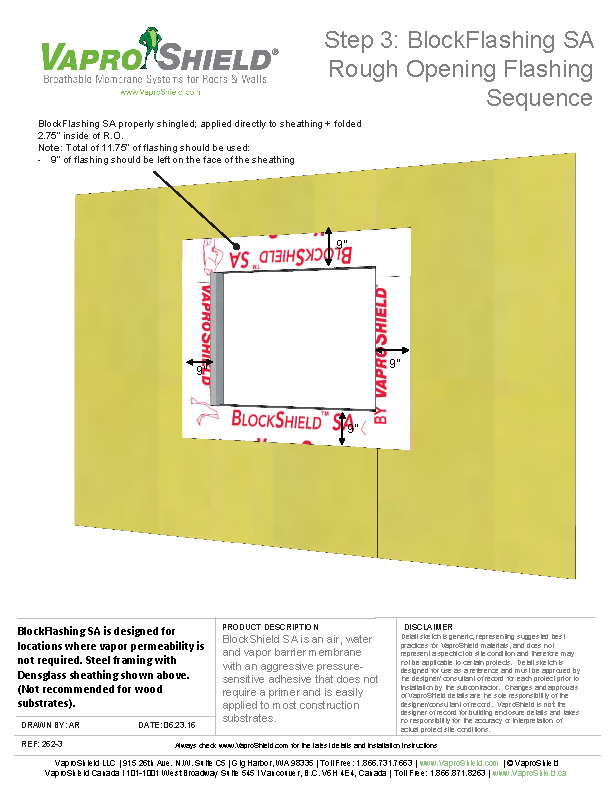

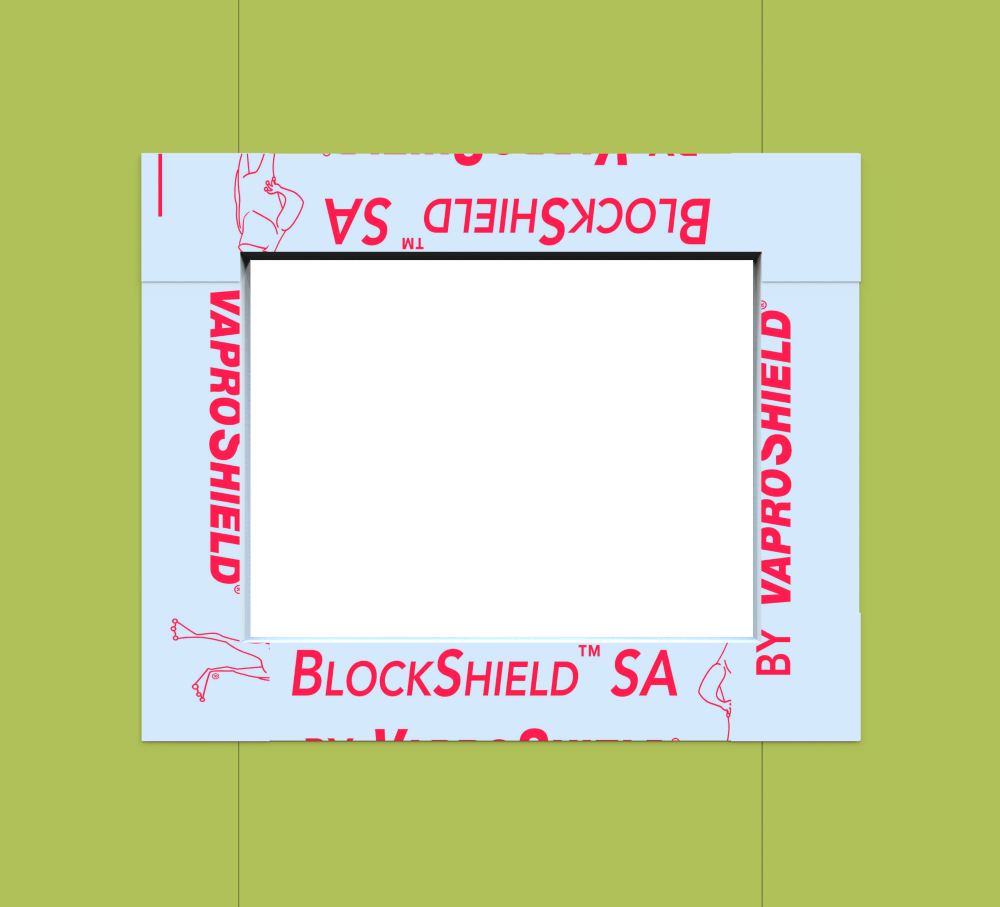

- Use as a rough opening flashing or transition flashing

- Aggressive pressure-sensitive adhesive

- No primer required

- 12 month UV and weather exposure

- AAMA 711-13 compliant

- Application temperature 20°F (-6.6°C) and rising

- Durable, tear resistant, and flexible at low temperatures

- Zero VOCs

- Multi-layer elastomeric film seals around nails and staples to prevent moisture intrusion.

- Compatible with many building sealants: no adverse reaction with synthetic rubber, butyl, polyurethane, silicone and silane terminated hybrid sealants.

![]()

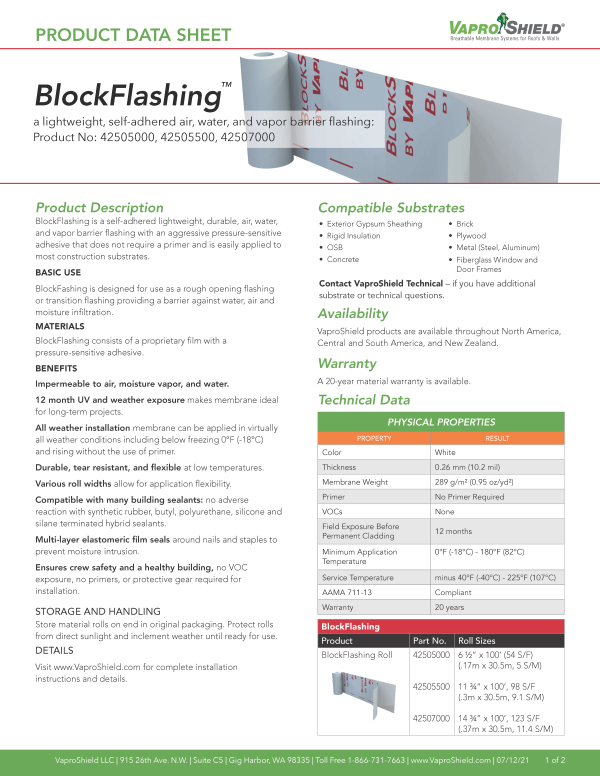

Three Convenient Sizes

|

|

|

|

BlockFlashing roll widths: 6 ½”, 11 ¾”, 14 ¾” (.17m, .3m, .37m) |

||

Air, Water and Vapor Barrier Flashing System

Installation

|

PHYSICAL PROPERTIES |

|

|

PROPERTY |

RESULT |

|

Color |

White |

|

Thickness |

0.26 mm (10.2 mil) |

|

Membrane Weight |

289 g/m² (0.95 oz/yd²) |

|

Primer |

No Primer Required |

|

VOCs |

None |

|

Field Exposure Before Permanent Cladding |

12 months |

|

Minimum Application Temperature |

20°F (-6.6°C) - 180°F (82°C) |

|

Service Temperature |

minus 40°F (-40°C) - 200°F (93.3°C) |

|

AAMA 711-13 |

Compliant |

|

Warranty |

20 years |

|

TESTING DATA |

||

|

PROPERTY |

STANDARD |

RESULT |

|

Strength |

||

|

Dry Tensile Strength |

ASTM D882 Standard Test Method for Tensile Properties of Thin Plastic Sheeting |

XMD - 3.85 N/mm (22 lbf/in) |

|

Dry Breaking Force (Grab method) MD ≥40 XMD ≥35 |

ASTM D5034 Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test) |

MD – 338 N (76 lbsf) CD – 356 N (80 lbsf) |

|

Cold Mandrel Bend Test |

AC38 Section 3.3.4 |

PASS |

|

Weathering Tests |

AC38 Section 4.1.2 UV Exposure AC38 Section 4.1.3 Accelerated Aging |

PASS |

|

Minimum Puncture Resistance |

ASTM E154 Standard Test Methods for Water Vapor Retarders Used in Contact with Earth Under Concrete Slabs, on Walls, or as Ground Cover |

56 lbf (249 N) |

|

Water Vapor Transmittance |

||

|

Water Vapor Transmission Using Modulated Infrared Sensor |

ASTM F1249 Standard Test Method for Water Vapor Transmission Rate Through Plastic Film and Sheeting Using a Modulated Infrared Sensor |

0.0193 Perm (grain/h•ft2•inchHg) 1.10 ng/Pa•s•m2 |

|

Adhesion Testing |

||

|

Adhesion after Water Immersion |

AAMA 711 |

PASS |

|

Water Resistance Testing |

||

|

Water Resistance (Control after Weathering) |

AATCC 127 Hydrostatic pressure test (550 mm water column for 5 hours), American Association of Textile Chemists and Colorists |

PASS |

|

Fire Testing |

||

|

Flame Spread Smoke Developed |

ASTM E84 Standard Test Method for Surface Burning Characteristics of Building Materials |

Flame Spread 5 Smoke Developed 15 |