pdf

Printer Friendly

(1.10 MB)

(PDF)

pdf

Printer Friendly Spanish

(866 KB)

(PDF)

Best Practices

- RevealShield SA Self-Adhered building layout should be planned prior to application to minimize waste, this process will assist locating penetrations that will need to be correctly detailed to ensure a weather and air tight installation.

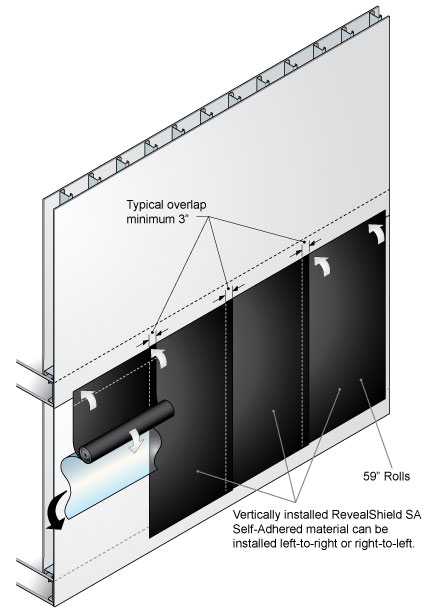

- RevealShield SA Self-Adhered can be installed in a vertical or horizontal direction.

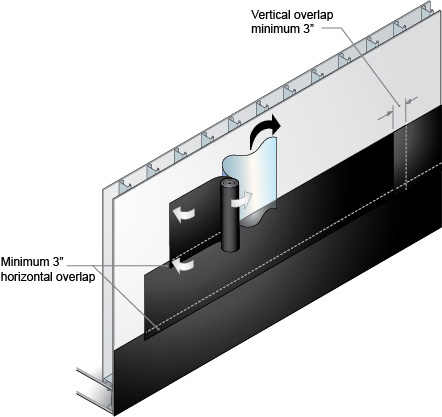

- Always install in a “weatherboard or shingle fashion” with the lower courses lapped under the upper courses.

- All penetrations including windows and doors must be installed in proper sequence to ensure a "weatherboard or shingle fashion” end result.

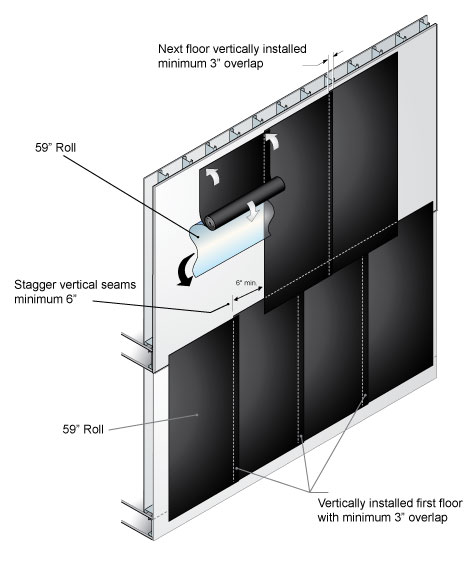

- All overlaps must be a minimum of 3” on horizontal and vertical seams.

- Inside and outside vertical corners should be minimum 6” of overlap.

- Vertical seams should be staggered from floor to floor, or separated by a RevealShield SA Self-Adhered horizontally applied strip.

- Roll membrane with two-handed roller to ensure proper adhesion to substrate.

- Sustains twelve (12) months UV and climate exposure prior to cladding installation.

Substrate Information

- The substrate condition is crucial to the adhesion performance of any adhesive membrane.

- Substrates must be clean and free of any contaminants.

- Substrate surface must be dry to the touch with the ambient temperature above 20°F.

- RevealShield SA Self-Adhered can be applied to a wide variety of sheathing substrates:

- GlasRoc

- DensGlass Gold

- Most rigid insulation

- Pre-painted steel

- Precast concrete

- Concrete block

- Plywood

- Aluminum (painted or mill finish)

- Cast-in-place concrete

- Galvanized metal

- Rigid vinyl

- Steel

- Anodized aluminum

- For OSB applications please contact our technical team, 866-731-7663 opt. 5, E: [email protected] or use our Contact Form

- Primer is not required or recommended.

Installation Practices

During the installation process, RevealShield SA Self-Adhered must be protected at the leading edge to ensure liquid water does not travel behind the membrane.

For Open Joint Cladding Systems

- Maximum open joint size between cladding components is up to 2” horizontal and ½” vertical open joints.

- Maximum 40% total open wall area

Adhesive Curing Time

- Normal curing time is approx. 6 hours.

- Full adhesion will vary depending on job site weather conditions.

Floor Line Movement

- Buildings are designed to accommodate thermal and seismic movement.

- RevealShield SA Self-Adhered must be installed to allow this movement throughout the life of the structure.

- To accommodate floor-line movement in wood frame construction: Limit coverage area to a single floor and shingle subsequent layers over the top leading edge.

RevealShield SA Self-Adhered IS Non-Directional

- Install pieces vertically or horizontally.

- Ensure “weatherboard manner” by installing pieces over the top of the pieces below.

- Pieces are easily cut to size.

Penetrations

- Please refer to Details page for method and sequencing.

- Always ensure weatherboard result is achieved.

Original Packaging Functions as Dispenser

- Keep RevealShield SA Self-Adhered in original packaging

- Carefully lift one end of the product out of the box and slide the plastic wrap off

- Replace the roll in the box/dispenser and carefully remove the tape in the middle of the roll.

- Keep plastic roll cover to protect partial rolls during installation.

Manageable Lengths

- Pre-cut material into individual manageable lengths for installation by pulling material off the main roll to the desired length.

- Cut material square to the factory edges.

- Re-roll material same direction it came off the roll, with the release paper outward.

- Cut material to desired length with extended blade razor knife.

- Tip: pre-cut material for desired lengths for rough openings. Label as needed on release film with marker.

Single Worker vs. Two Worker Installation

- Using the material at its full width, 59”, vertical installation can be easily accomplished by a single worker.

- Horizontal installation of the full width material is best accomplished by two workers.

- Partial width rolls are easily installed by a single worker.

* Please see the Details for further clarification.

Vertical and Horizontal Installation

- Horizontal installation of the RevealShield SA Self-Adhered material is similar to the vertical installation method.

- The material can be applied either left to right, or right to left

Best Practice Installation Sequence

- Snap a level chalk line for guidance

- Pre-cut material to desired length

- Roll material with release paper facing OUTWARD

- Starting at a corner of the roll, peel back approx. 6” of release paper

- Cut the release paper with razor knife and tear the cut portion of the release paper exposing approx. 6” of glued surface

- Using hand pressure, lightly apply the exposed glue surface to the substrate

- Starting in the middle, use your hands to smooth out air bubbles, releasing the air to each side

- APPLIES ONLY TO VERTICAL INSTALLATION - Allow the rolled up material to drop down the wall, with the remainder of the release paper still attached, checking for proper alignment

- Reposition as needed - the material is very forgiving allowing for easy re-alignment

- When aligned, apply heavy hand pressure across the entire adhered section

- Roll up the material with release paper facing OUTWARD

- Slowly pull the release paper down the wall, allowing the rolled up material to unfurl

- Lightly smooth out air bubbles with wallpaper trowel

- Continue until all the release paper has been removed

- Pull back and reposition material (if necessary) as it unfurls

- Roll membrane with two-handed roller to ensure proper adhesion to substrate.

- Proceed with next step, ensuring a 3” minimum overlap to the adjoining material, always in a weatherboard manner

Installation Best Practices

- Avoid scoring the membrane at locations where the material overlaps onto the adjacent piece.

- Allow the top layer of material to span across the underlying layer without attempting to force the material into a 90° bend.

- Avoid stretching the material during installation at inside and outside corners.

- A full 6” overlap in either direction is recommended vertically at inside and outside corners.

- If desired adhesion is not attained between membranes due to site conditions, VaproShield recommends applying a bead of VaproBond as an additional solution to pressure rolling.

Storage

- Must be stored vertically

- Must be kept dry

- Must be stored in temperatures between 40° F and 120° F (4ºC - 49ºC)

THIS IS NOT A SEQUENCE OF INSTALLATION STEPS. EACH IS A SEPARATE SCENARIO

|

|

| Horizontal Installation | Vertical Installation |

|

|

| Multi-Floor Vertical Overlap | Vertical Installation with Horizontal Floor Line |