Safety

Underlayment membrane is slippery when wet. Workers should use shoes with sufficient sole friction to avoid sliding or slipping on the material. Avoid walking on this material when wet. Use good roofing practices, always wear fall protection when working on a roof deck.

Overview

RoofBlock HT is a high temperature roofing underlayment composed of a high strength slip resistant spider web backing laminated to a high-performance, high temperature asphalt compound with a film release for ease of application. The release liner is removed leaving a strong asphalt compound to bond to the roof deck.

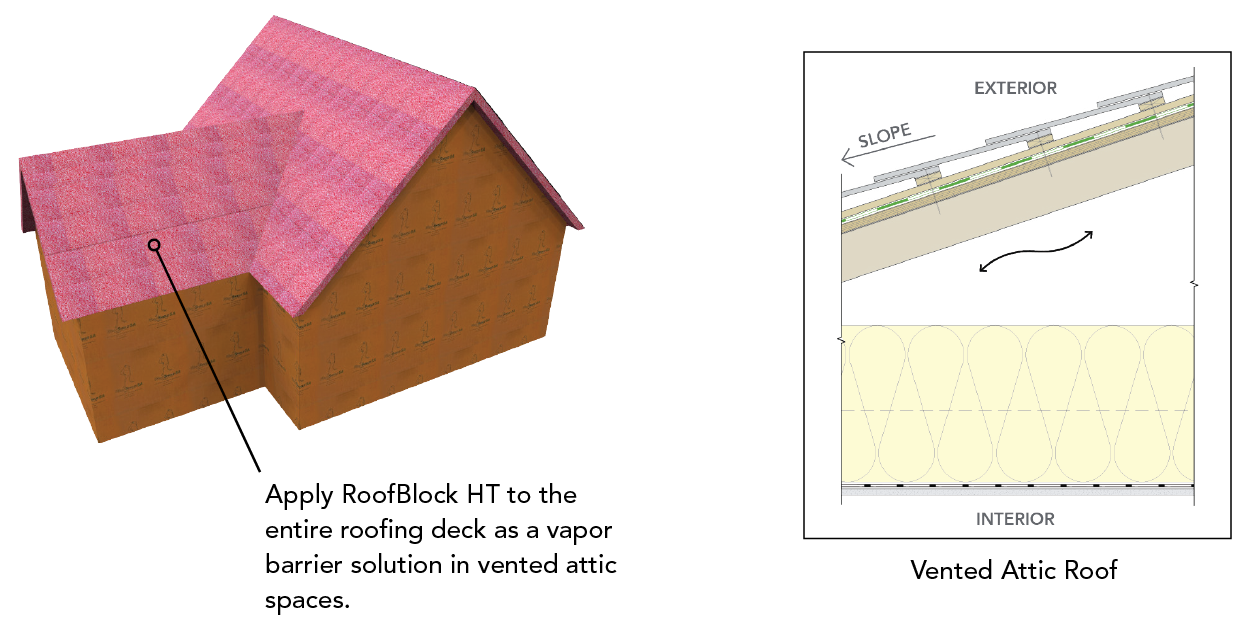

RoofBlock HT may be used on sloped vented roof decks.

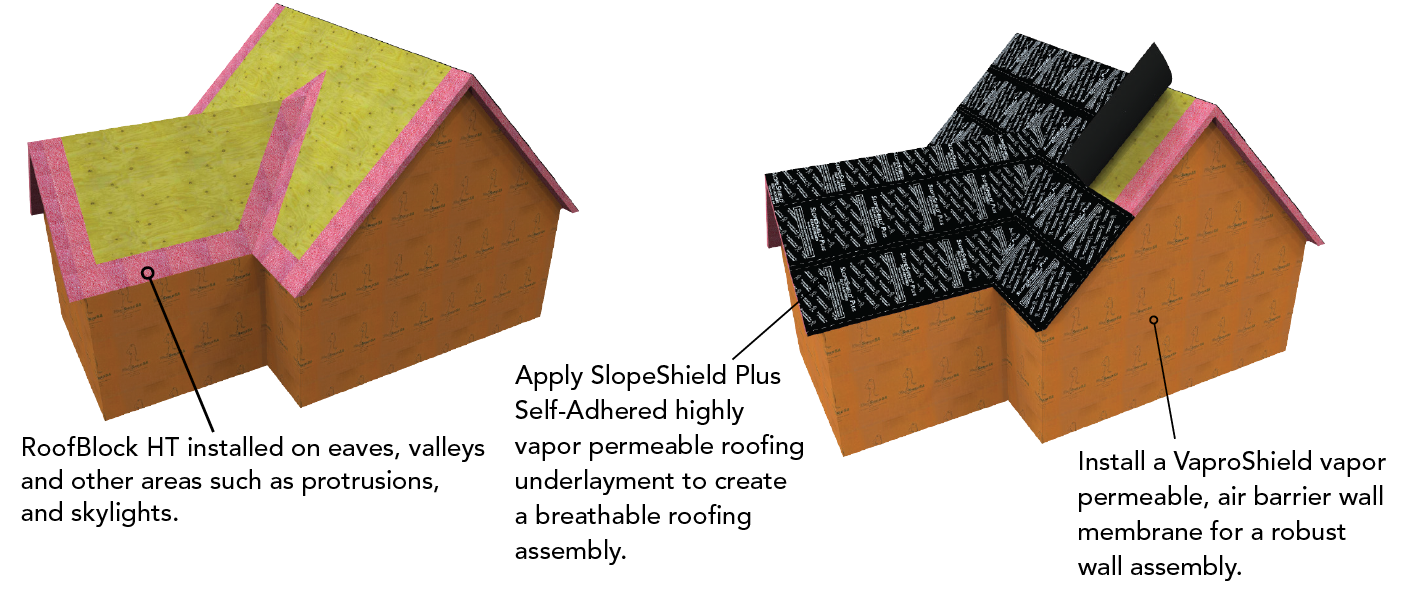

RoofBlock HT can be installed on eaves, valleys, and other areas such as protrusions, and skylights for ice damming protection in conjunction with SlopeShield Plus SA roof underlayment.

RoofBlock HT may also be used as a total roofing underlayment over vented attic spaces for water protection under the primary roof system.

Storage

Materials should be delivered in a manufacturer's original, unopened packaging with labels attached. All materials must be handled in a manner to prevent damage. Any material damaged must be removed from the project area and replaced with new material. Products must be handled in accordance with manufacturer’s guidelines. Material Safety Data Sheets must be reviewed for guidance on flammability and other dangers of any primers to be used; instructions for safety should be fully followed.

Substrate Preparation

RoofBlock HT can be installed directly to a clean dry structural deck. All dust, loose nails, old roofing materials and dirt must be removed prior to application of the membrane. Decks must not have voids, unsupported or damaged areas. Wood plank substrate must be butted tight together. The underlayment cannot span a crack larger than 1/16" (1.6mm)

Prime as needed, but never apply primer to wet or frozen surfaces. If surface temperatures are 32°F (0°C) and rising, RoofBlock Primer SB or California Sealant may be used to promote adhesion. If surface temperatures are 40°F (0°C) and rising, RoofBlock Primer WB (water-based) may be used to promote adhesion.

The underlayment should be kept warm until needed if cold temperatures exist. When substrate is ready, apply RoofBlock WB at a rate of 350-400 sq. ft. per gallon, RoofBlock Primer SB or California Sealant at a rate of 250-300 sq. ft. per gallon, depending on porosity of the substrate and using a short nap roller or brush. Allow the primer to dry for one hour or until tack-free. Prime only the area that can be covered with RoofBlock HT on the same working day. Areas primed and not covered within 24 hours should be recoated.

Do not apply primer at heavier rates than recommended. Excessive material build-up will delay drying and underlayment application. Primer must be used on masonry, concrete or gypsum. If wood composite and gypsum sheathing adhesion is marginal, adhesive should be used to enhance adhesion to the substrate. Roofing material can be applied promptly over RoofBlock HT.

Best Practice Installation

On standing seam metal roofs RoofBlock HT will be applied on insulation board. The underlayment should be applied with a 6-inch minimum end and a 3-inch side overlap. Cut RoofBlock HT into 10-15 foot lengths and re-roll. Starting at the base or lower edge of the roof, apply underlayment with the long edge parallel to the edge of the roof. Unroll RoofBlock HT by pulling the release sheet from under the underlayment. Roll the surface with a small hand type roller or hand pressure during application to eliminate minor wrinkles and air pockets.

Most local building codes and the National Roofing Contractors Association recommend underlayment application from roof edge to 24-inch within the interior wall line of the building. Since snow loads vary by area, local conditions should be considered during specification.

Apply RoofBlock HT to ridges or valleys, slit to proper width and with approximately half of the underlayment width applied on either side of the ridge or valley. Cut the underlayment into approximately 6-foot lengths for placing on irregular contoured surfaces for ease of application. Install roofing valleys from the low point to the high point, shingling RoofBlock HT. Overlap all ridge and valley underlayment by 6-inches. In mountainous areas with considerable snow, it may be necessary to apply RoofBlock HT. Repair holes, tears, fishmouths, and any damage to membrane with a piece of RoofBlock HT extending past the damaged area a minimum of 6-inches in all directions. Fasteners or screws must stay in but if removed they must be patched. RoofBlock HT may not self seal around these areas.

Limitations

Avoid folding the underlayment over the roof edge unless protected by flashing, gutters, or drip caps. If drip caps are used, do not install underlayment on top of the drip cap. RoofBlock HT can be folded over the roof edge underneath the drip cap. RoofBlock HT cannot be guaranteed for UV stability if left exposed for over 60 days. If extended UV stability is required over 60 days, cover RoofBlock HT with SlopeShield Plus SA. RoofBlock HT is not compatible with EPDM or TPO roofing systems. Do not allow RoofBlock HT to come in contact with flexible PVC, polysulfieds or high concentrations of resins such as pitch.

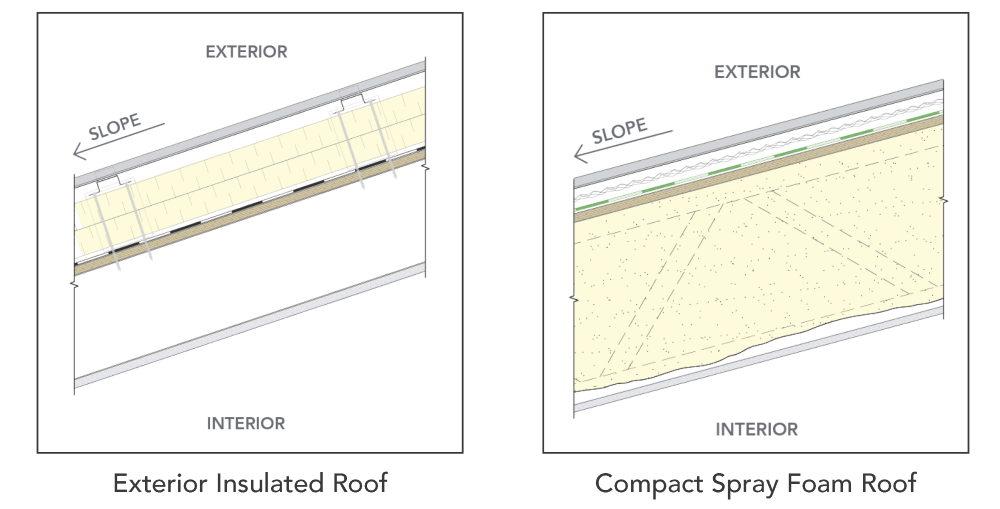

Permeable Roof and Wall System

Vapor Barrier Roofing system - Vented Roof Design