Installation Instructions (PDF)

Tools and Accessories

|

|

|

|

|

| Two-handed Weighted Roller |

Gloves |

Sausage Gun |

Flashing Accessories |

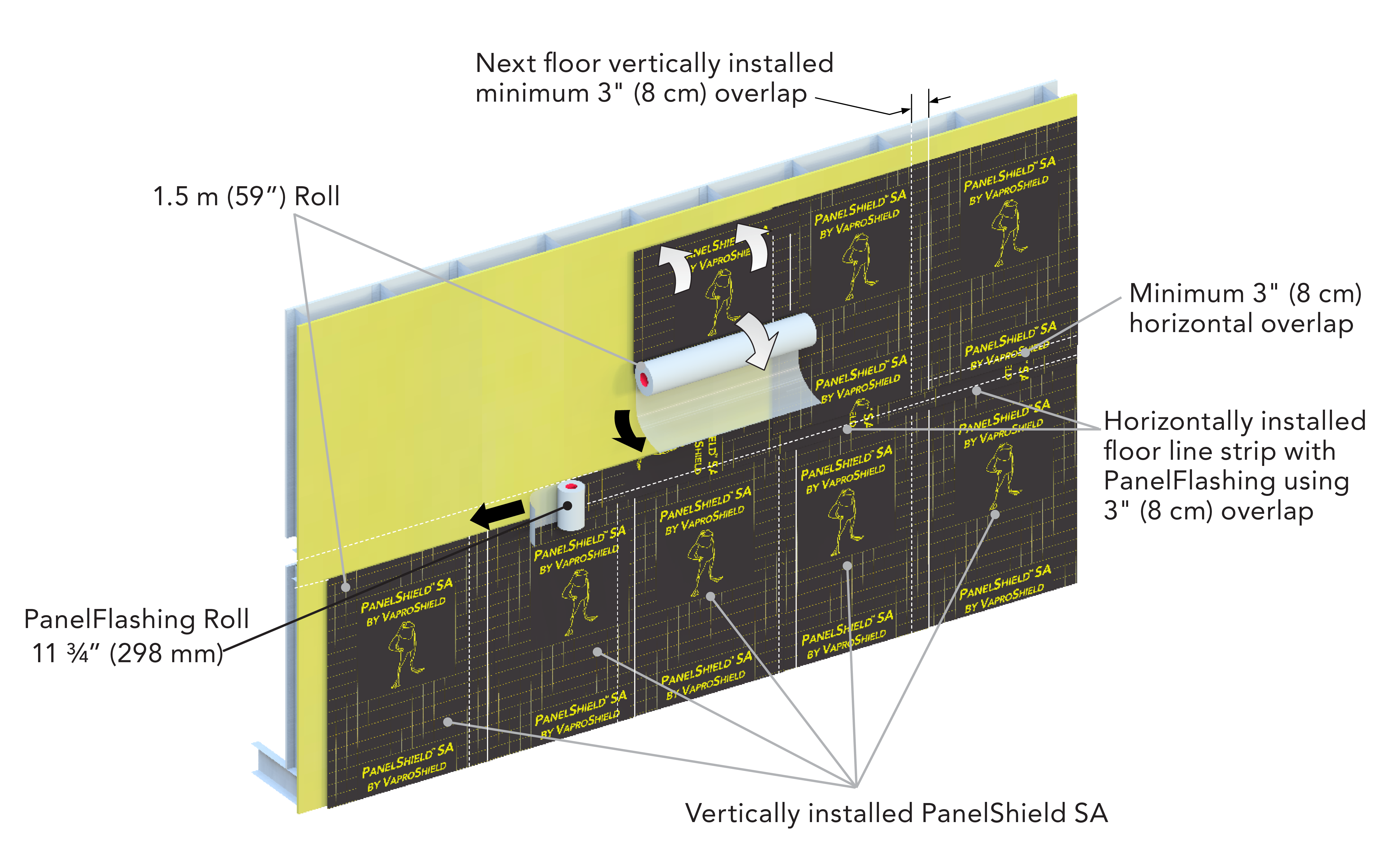

11 3/4" PanelFlashing |

Compatible Substrates

- Exterior Gypsum Sheathing

- Rigid Insulation

- OSB

- Concrete

|

- Brick

- Plywood

- Metal (Steel, Aluminum)

- Fiberglass Window and Door Frames

|

Delivery, Packaging And Storage

- Store materials on end in original packaging.

- Protect rolls from direct sunlight and inclement weather until ready for use.

Substrate Preparation

- Substrates must be clean and free of any contaminants.

- Substrate surface temperature must be dry to the touch with the ambent temperature above 20˚F (- 6.0˚C).

- PRIMER IS NOT RECOMMENDED OR REQUIRED

Climate and UV Exposure

- Sustains a maximum 12 months UV and climate exposure prior to cladding installation.

| Do's |

Don't's |

- DO roll membrane with two-handed roller to ensure proper adhesion to substrate

- DO install above of 20˚F (- 6.0˚C) and rising

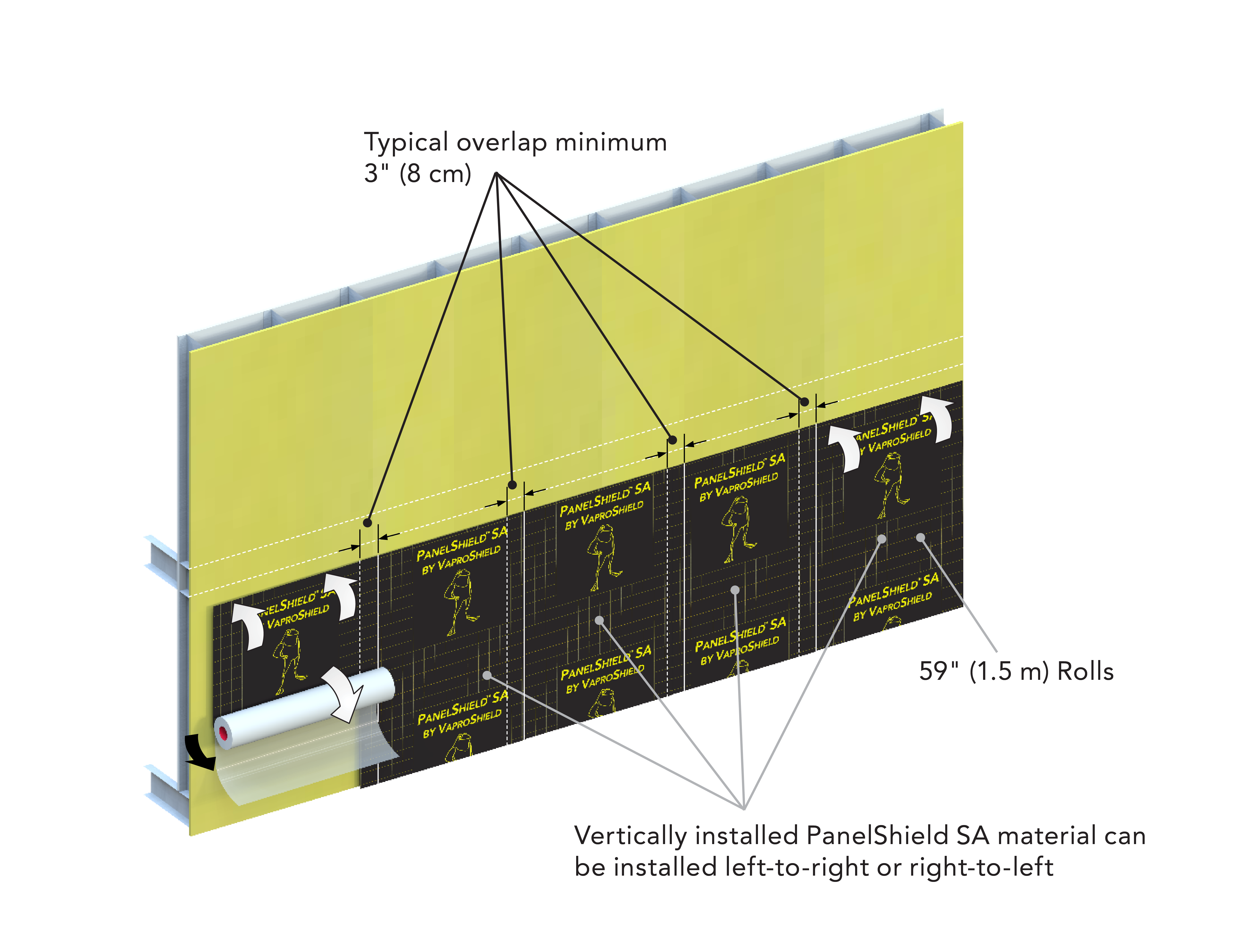

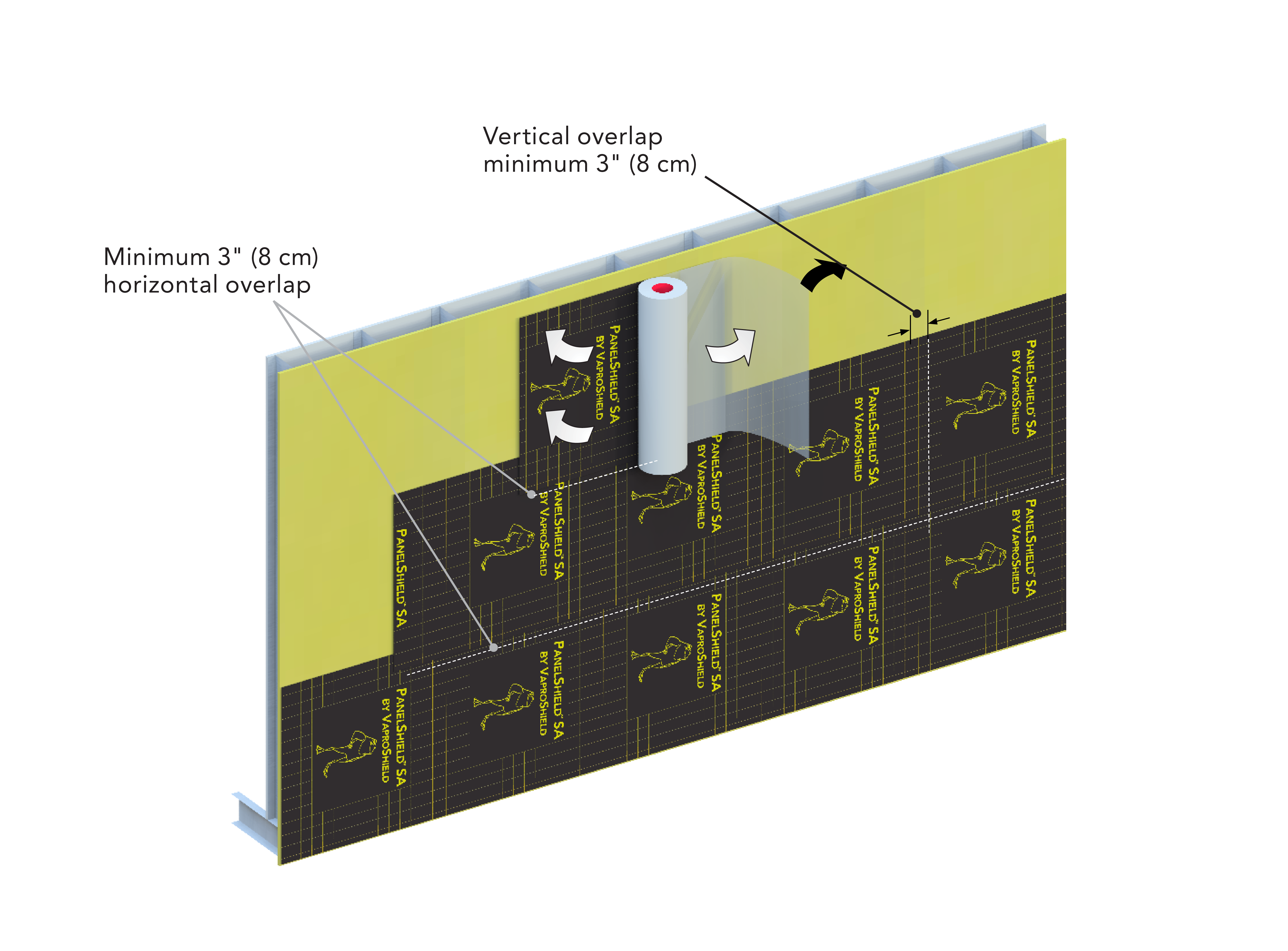

- DO install in a "weatherboard or shingle fashion"

- DO cut membrane using basic hand tools

- DO ensure surfaces are in sound, clean condition and free of oil, grease, dirt, excess mortar or other contaminants

- DO fill voids and gaps in substrate greater than 7/8” (22.2 mm) wide

- DO use behind closed-joint rainscreen cladding assemblies

- DO apply a bead of VaproBond if desired adhesion between membranes is not attainable due to site conditions

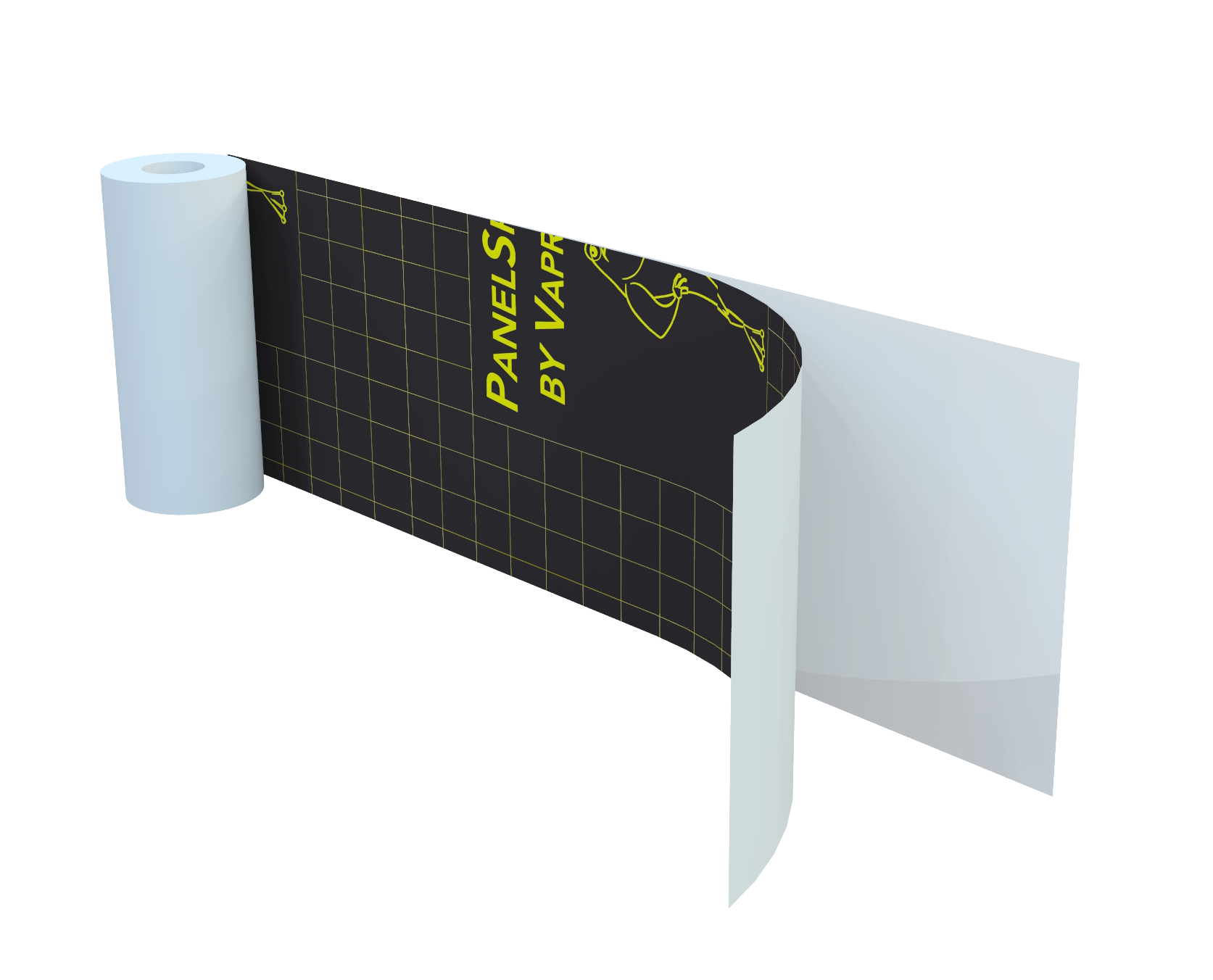

- DO remove release liner from under foot as soon as the membrane is installed (red)

- DO properly dispose of the release liner

|

- DON'T install reverse laps that can result in water ingress

- DON'T leave exposed to UV and weather for over 12 months

- DON’T install below 20˚F (- 6.0˚C) and decreasing

- DON'T install over gals greater than 7/8” (22.2 mm) wide unless filled

- DON’T store materials in direct sunlight and inclement weather until ready for use

- DON'T install on dirty or contaminated substrates

- DON'T use primer

- DON'T leave release liner underfoot

|

Safety

- Work crews are safe around VaproShield membranes.

- PanelShield SA contains zero VOCs or toxins.

Adhesive Curing Time

- Full adhesion will vary depending on job site weather conditions.

- Pressure with roller is required.

Technical Guidelines

|

|

Best Practice Installation

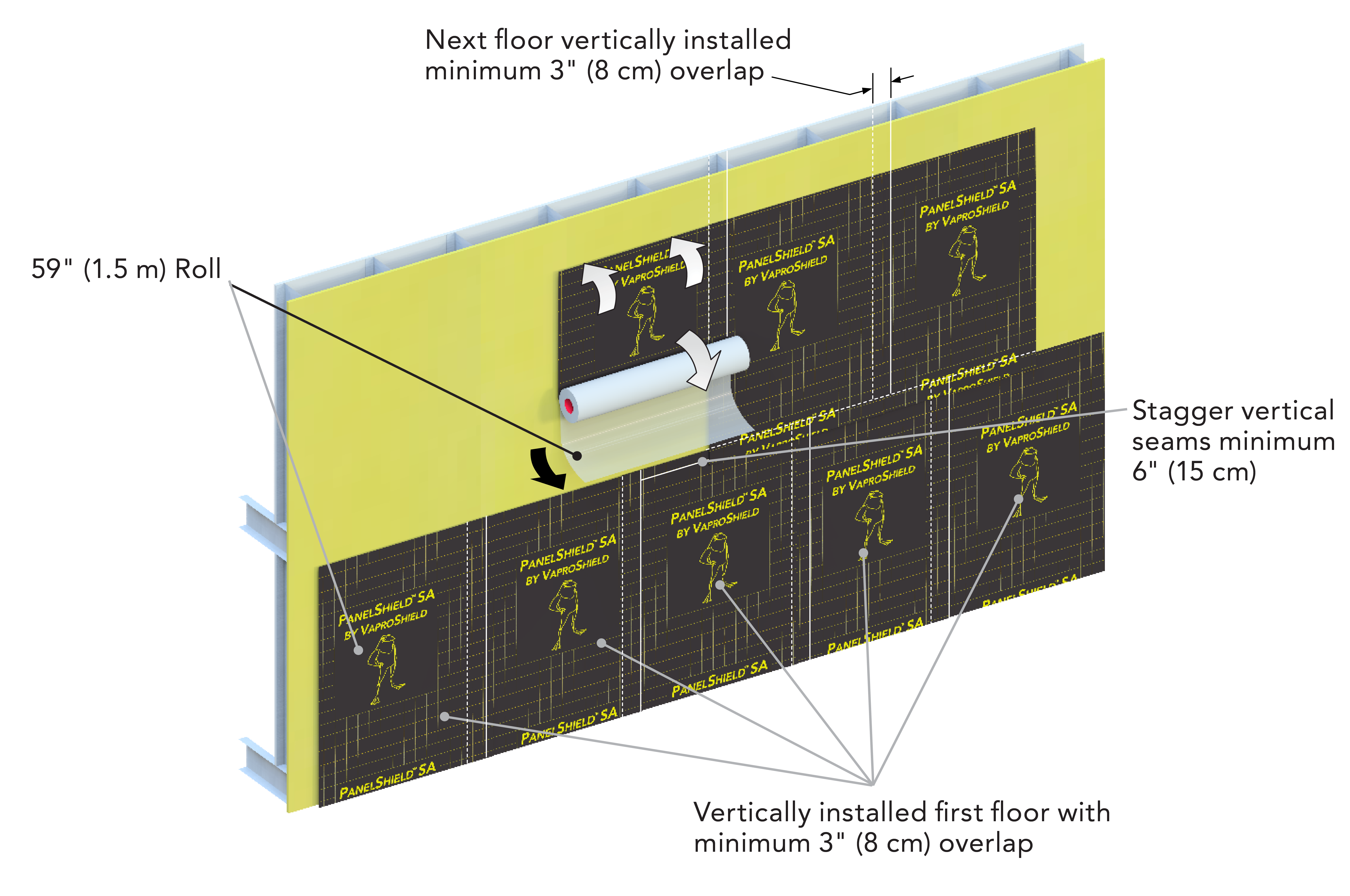

All overlaps must be a minimum of 3" (8 cm) on vertical and horizontal seams. Inside and outside vertical corner overlaps should be a minimum 6" (15 cm) in both directions, staggered a minimum of 24" (61 cm), and should not occur directly above or below windows or doors. Use a roller to activate pressure-sensitive adhesive.

|

| CAUTION: Release liners are slippery. To prevent injury, liner should be removed from under foot as soon as membrane is installed and disposed of properly. |

Installation Best Practices:

Note: This is NOT a sequence of installation steps